|

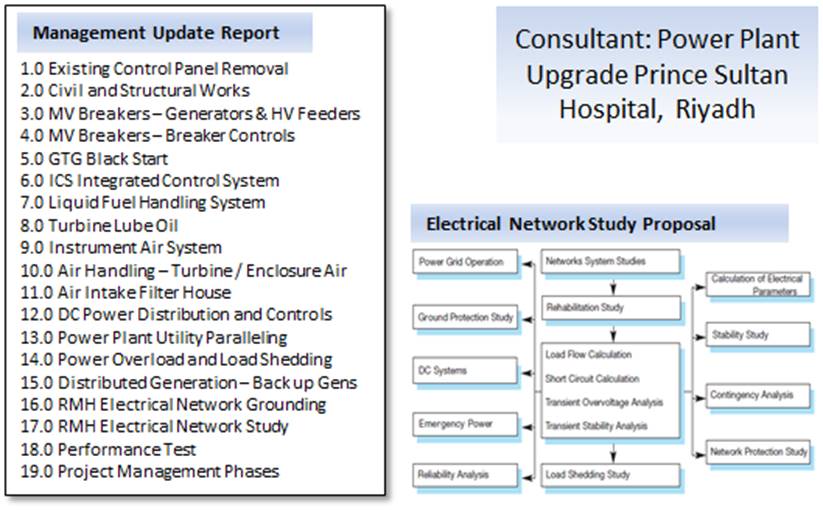

“Mike worked as Consultant / Engineer to help us

develop the concepts for the new power plant upgrade of Prince Sultan

Military Medical City power plant project in Riyadh…. …very professional in his approach, his methodical work

disciplines, knowledge, experience and work execution and his technical ability …I feel his involvement would be an asset to any

company who takes up his services.” Lee Robinson Technical Director Bandariyah Int. Co. Ltd. Kingdom of Saudi Arabia

_______________________ “(Mike) …in

the capacity of Owner's Engineer… impressed me with his experience and depth

of understanding of construction and quality controls in instrumentation,

industrial process, electrical generation and

distribution…. ….critical to our ability to understand and document the results of our

commissioning activities …. to clearly interpret events and quickly take corrective action Mike's friendly and personable nature

contributed to positive working relationships” Graham Jubb Project / Site Manager FICHTNER GbmH & CO

“….during his role as a Gas Turbine

Machine Controls Engineer… [he] had to learn the tools and process … looked

at the process and how to improve it.

… worked on several documents

…. This setup future engineers to that joined the team to get started

faster. He led several projects and grew his expertise. He leveraged people in India and the US

demonstrating that he can work with a global team. …did what was needed to deliver a quality

product on time. …took on more

difficult projects… always spoke up to make sure things stayed on time. …He is respected by his peers and

leadership.” Mark Luebbert Program Manager -Gas Turbine Controls

_______________________ “Mike acted as our Director of Turbine Services and was

lead engineer on a very complex and challenging project… Mikes responsibility was to initially assess the

overall condition of the project to identify obvious deficiencies and to

propose a plan for a satisfactory completion. He proceeded to pull together a support team of

engineers, technicians and constructors… … proved to be a highly skilled

professional, committed to the highest levels of customer service, and would

be a benefit to any project requiring innovation and leadership.” Jose D. Pekkatil General Manager Bennet Engineering

“As a Controls & Commissioning Engineer, Mike was

responsible for several gas turbine installations including multi-unit sites

running concurrently … … on the controls side, Mike has dealt with writing, installing and troubleshooting controls… …during this time, he has impressed me and my

colleagues with his technical ability and professionalism… … Mike’s ability to project manage

and work with people combined with his technical expertise has ensured that

all the projects he worked on have run smoothly and efficiently…” H. Malone C Eng. Customer Support

Supervisor, European Gas Turbines _______________________ “… having a thorough grounding in microprocessor

based controls systems and being able to master the problems of

bringing complex equipment on line safely… …Mike’s work ethic is solid and reporting accuracy is

second to none.” Dr. Roger Lowder Training Manager European Gas Turbines

_______________________ “Mike proved to be excellent in taking appropriate

risks and suggesting creative solutions.… … the project involved the integration of a combustion turbine with a

unique external low NOx combustor and a coal gasification cycle. …offered innovative solutions to controls issues that arose. …maintained a determined attitude through many delays

and priority changes… …I am confident that Mike would be an excellent

addition to your organization.” Frank Morton, Principle Engineer, Southern Company

_______________________ “…Mr. Courchesne's technical expertise was an integral

part in overcoming many challenges… …(his) highly developed trouble shooting skill was an

important factor in maintaining the units during the Process Plant Start

Up... ... instrumental in providing essential personnel

training to Maintenance/Operations Technicians during the first year of

operation” Mike Maloney MAR Eng,

Maintenance Supervisor Searose

FPSO Husky Energy

_______________________ “…his controls expertise, attention to

detail and organizational skills proved invaluable… …Mike's ability to anticipate, document & front run

the punch issues meant the controls team was always several steps ahead and

allowed for a safe and controlled start up of the

unit. Mike's positive

attitude and approachable style certainly helped to offset the long hours

that were needed on this particular project. I am confident Mike would make a valuable

contribution to any team he joins.” Mario Papini, PEng, Senior Project Manager Union Gas Limited

_______________________ “…Mr. Courchesne has extensive experience in the

verification and functional analysis of control systems… …works in

support of our engineers in the installation and commissioning of our turbine

engines. ” Rick Aker, Field Service Manager Rolls-Royce Energy Systems Inc.

|

|

|

Michel Courchesne, C.E.T. Instrumentation and

Automation Specialist for Process and Machine Controls Commissioning,

Installation, Operations, Maintenance & Reliability Mgmt. Certified Controls Engineering Technologist OACETT, Canada. e-mail mikec@2156corp.com Professional Objectives: · To work as part of a high-performance team to

successfully improve processes, execute complex and challenging tasks on time

and on budget. · Demonstrate leadership in the areas of communication,

planning, time management, risk mitigation and negotiation. ·

Promote

teams and individuals by integrating their skills with collaborative

workflow, and effective strategies to improve the outcomes for all

stakeholders. Principle Skills: · Process and Machine Control Expertise: Gas

Turbines / Power Generation / LNG / Compressors & Pumping Stations / High

Purity Water Treatment / Steam Generation / Steam Turbines / Petrochemical

& Combustion Reactors / Chemical & By-Products Refining · Global

work experience onshore, offshore and in remote and harsh environments, and

applying cultural competence and promoting teamwork. · Excellence

in technical execution, team leadership, supervision, communication, while

management skills. · Highly

developed expertise in the planning and execution of applied research for

problem solving relating to commissioning, construction, operations, and

maintenance activities with superb troubleshooting, technical documentation and reporting skills. · Team

player in the participation, planning and execution of work plans, inspection and test plans (ITPs), method statements,

commissioning and start-up, maintenance

planning for turnarounds, planned and unplanned outages. · Drive improvements in key performance indicators

for Reliability & Asset Integrity excellence following standard methods

for effective Reliability-Centered Maintenance processes i.e.

SAE JA011 · Perform Safety Integrity Level (SIL) studies for

SIF / SIS (Safety Instrument Function & Safety Instrumented System) · Assess failure modes and forecast functional

failures. Perform Root Cause Analysis, develop resolutions, and proactive

tasks of maintenance/inspection intervals to improve reliability. Coordinate

/ oversee Management of Change (MOC) programs. ·

Extensive

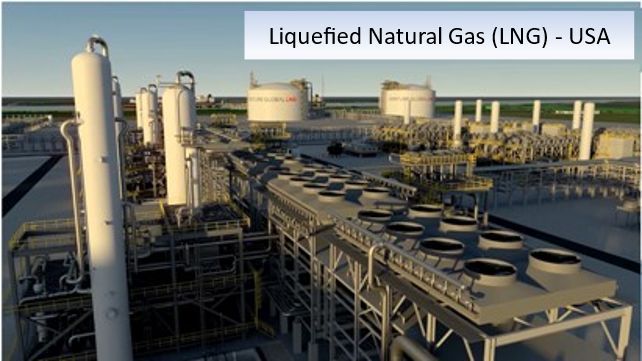

controls software expertise and the ability for design and

hands on check out and functional testing of processes, instrumentation

(field devices, sensors, actuators, PLC, DCS & HMI); electrical devices

(generators, motors, VFDs,), verification of mechanical operation and control

of major components and system control philosophies. · Apply

new technologies and innovative strategies for communication, reporting and

metrics tracking. Employ and customize

team collaborative tools, basic web-based project management applications,

and business automation tools for effective communication and streamlining

workflows. ·

Control Coding Expertise,

structured text, ladder logic, function blocks, scripting, refactoring,

macros etc. ·

Innovation and creativity in

overcoming obstacles and a breadth of experience in development of 1st

generation technologies. ·

Provide leadership, technical

support, on-site mentoring of junior engineers, formal and informal training

for clients and other technicians and engineers. ·

Team Leader

or as part of the team, a capacity to motivate and educate others to a higher

level of professionalism in a safe working environment. Clients Served: ·

Various,

Construction, Commissioning, Operations & Maintenance since 2009. ·

Rolls-Royce

Energy Systems Inc. Gas Turbine E&C Commissioning, 1996-2009. ·

GEC Alsthom / European Gas Turbines, Electrical & Controls, 1990-1996. Language Proficiencies: ·

IR5 English,

IR4 French, IR3 Spanish, IR3 Portuguese Education and Professional Associations /

Publications: ·

Engineering

Technologist: Certified and registered in province of Ontario, Canada, since

1991. C.E.T. membership ID 58921, ·

Co-Inventor,

U.S. Patent 6350220 & 6447431, Euro PCT/CA2000/001113

Strength Automation System, published in Popular Science Magazine 2008. ·

Scientific

Research & Experimental Development Program (Canada) 2004-2006 Academic Background, Certifications

Industry Training: ·

2007 Engineering Technologist Certification: (equ 3 yr

Engineering Science Degree) OACETT Canada. ·

2007 Engineering Technologist Certification: OACETT Canada, ·

2000 Certified Technician Registration: OACETT Canada ·

1984 Diploma: Process Control I & II; PLC Controls, Mohawk College

/ IMI Tech. ·

1981 Apprenticeship Dofasco Steel Co. Control Theory I & II,

Instrumentation for the Steel Industry and Distributed Control Systems I, II

& III. ·

1978 Certificate of Technical Endorsement (3 Years) Instrumentation and

Control included Instrumentation and Process Controls I, II & III,

Electronics, Drafting, and Computer Sciences. Industry Experience: ·

Gas Turbines: GE’s LM/TM2500, LM1600, LM6000, Rolls-Royce RB211, Trent,

Allison. Selected Siemens SGT Series

GE LM-Series & Frames. Pratt & Whitney FT8 Twinpac,

Swiftpac. ·

Instrumentation & Controls: various PLCs / DCS / HMI including

Allen Bradley Control Logix, Siemens Simatic & S7, Woodward MicroNet,

Rolls-Royce Entronic, EGT Rustronic,

GE Mark IV, GE Fanuk, Hawker Sidley, Intouch

Wonderware ·

Gas Compressors and Pumps: Various 2000 to 20000 hp. ·

Electrical and Power Gen:

Various Generators 3 – 250 MW, Generator Protection, Synchronizing and

Islanding, Load Sharing, Excitation Controls, VAR Sharing. Work History: Venture

Global LNG for Baker Hughes Feb 2022 - present: · Senior Controls Engineer: Support the construction and commissioning

activities for the liquefaction trains for VGLNG 11 MTPA LNG Plant. GE

Controls Alliance Quest-Global Jan 2020 to Jan 2022: · Senior Controls Engineer: Support software modifications and controls

upgrades for General Electric Frame 7Fa 200+ MW Gas Turbines in conjunction

with their engineering team in Greenville South Carolina. Contract:

Siemens (Turkey, Abu Dhabi, Doha) July 2017 to July 2020: · Gas Turbine Machine Controls Engineer: Support the installation and commission of 5 x

Trent 60MW Phase IV GTs in Abu Dhabi including GTG installation,

instrumentation, controls, communications networks, HMI enhancements, MV

(MCC) and HV (Gen) commissioning for this 300 MW power plant. · Plant Maintenance Support Engineer: for 9X Trent GT – Compressor drives and

auxiliaries for the 2 bil. cuft/day

Dolphin Gas Project in Qatar, including maintenance planning for turnarounds,

planned and unplanned outages, root-cause failure analysis and prevention of

reoccurrences. Contract:

Panama Aug 2016 July, 2017: · Business Process Automation Engineer: Independent start up. Integrating applications, developing

software applications for collaborative management and information

technologies to restructure labour resources and

reduce costs across the business organization. Contract:

General Electrical / Granite Sept 2015 to Aug 2016: Saudi

Arabia: · Gas Turbine Machine Controls Engineer –Installation and commission of 4 GE TM2500+

including initial power up, controls check out and Turbine Crank. Sharm El

Sheikh, Egypt: · Gas Turbine Machine Controls Engineer – Supervision of 12 O&M Staff, development

and application of best practices and OJT for the Client’s Commissioning and O&M teams. This site incorporated 6x GE LM6000 SPRINT

series, Dual Fuel Gas Turbine Generators sets, with a BOP including Gas

Compressors, Liquid Fuel Supplies, 66KV and 220 KV distribution networks.

Lead the formation of operations team and oversee the first months of on line operations for power production to the local

government’s electrical utility. Evaluate

and recommend necessary OEM controls and mechanical spare parts and options

for alternate spare parts sourcing. Contract:

The Energy Consulting Group (ECG): Aug

2014 – May 2015 Abidjan,

Cote d’Ivoir, West Africa: · Owner’s Engineering for I&C and Commissioning – oversee construction,

testing and commissioning phases of this 288 MW open

cycle power conversion to 420 MW Combined Cycle Plant performed by HDEC

(Hyundai Engineering and Construction).

Supervision of execution of the EPC contract, the tracking of the progress,

quality control of the construction and the indication of corrective action

where necessary. Analysis of

commissioning activity results, investigation and recommendations based on

data from the distributed control system alarm and event logging. Recommendations

for Sequence of Events improvements for enhanced troubleshooting and

root-cause failure analysis. Contract:

APR Energy LLC: July 2013 – Aug 2014: Middle

East / North Africa: · GT Availability and Reliability Manager MENA

Region – Supervision of 26 Field Service

engineers for 5 Fast Power installations in the region including 20 x TM2500

mobile gas turbines, the associated liquid fuel delivery systems and HV

distribution systems. Identified function standards, functional failures,

failure modes and effects, consequences and develop proactive tasks and

maintenance / inspection intervals to improve the delivery of GT power to APR

customers. Created a Management of

Change system (MOC), coordinated the activities and of technical service

engineers in the region, created a Shutdown Reporting System using Microsoft

VBA to standardize and automate communication of high cost

events, collaborate with the stakeholders and provide a real time dashboard

for availability of 52 gas turbines around the world. Tripoli,

Libya: · Country Maintenance Manager: Supervision of 8 field service engineers and

lead the local teams of GT Specialist, support cross training to junior

engineers in support of the performance objectives Basra

Iraq: · GT Site Management (120 MW), Al Hartha Power:

Supervision of 22 O& M Staff. Responsible for the effective

implementation of the business, operations and

maintenance plans for the plant. Kone, New

Caledonia: · GT Site Management (60 MW), Koniambo

Nickel Mine: Supervision of 14

O&M Staff. Representing the

operations department in the installation of the fast-track power plant,

participating in customer meetings, develop operating procedures, management

of the operations and maintenance staff, development and implementation of

the best practices, business, operations and

maintenance plans for the plant. Contract:

Shannon Power Management Limited - Oct 2011 to July 2013: Western

Australia: · Commissioning Manager – Supervision of 50 field engineers, skilled

trades and admin staff for Citic Pacific Mining,

Desalination Plant at the Sino Iron Mine: -support and mentoring in the

application of engineering technology and best practices for commissioning

this world scale desalination plant.

This major infrastructure project produces up to 70 megalitres of desalinzed water

per day and includes a sea water intake pumping station, 22 km pipeline,

pretreatment, HP Pump. Reverse Osmosis and a 12 megalitre

product tank. · Construction and Management Application Engineer – develop software application for Task and

Progress Management including automated Time and Attendance Tracking, Task

Scheduling, integration to MS Project or Primavera, Event Reporting, Cost and

Schedule Performance Indices calculations.

Saudi

Arabia: · Power Systems Engineering - Riyadh Military Hospital: Front

End Engineering and Design (FEED) for the rehabilitation of the power plant

including optimizing availability and reliability by assessing fuel systems,

DCS controls and electrical paralleling and load sharing with the national

power utility using 3 TurboMach Triton (Solar) Gas

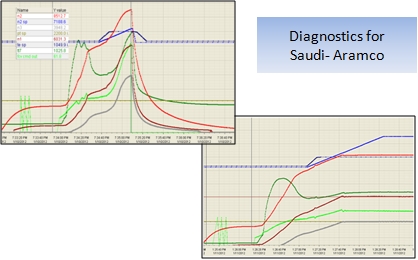

Turbines. · Turbine Controls Specialist - Saudi Aramco: integration and commissioning of

new Siemens Controls for Gas Turbines across the fleet of the East West

Pipeline; perform analysis and provide recommendations for controls

modifications to mitigate potential overspeed conditions. Contract:

Power-House, Dec 2010 to Oct 2011: United

Arab Emirates, Ras

Al Khaimah: · Director, Project Manager and Senior Engineer – Supervision of 18 field service engineers and

skilled trades for the JBF Plastics Power Plant Expansion. This twin gas turbine cogeneration plant

(RR KB-501s) was abandoned by the previous contractor. - Assess and oversee all aspects of

engineering and rework for completion including major mechanical repairs,

overhaul of control system, the design and implementation of a Liquid / Gas

dual fuel system, the set-up of electrical load sharing, the completion the

performance test and the start of commercial service. Contract:

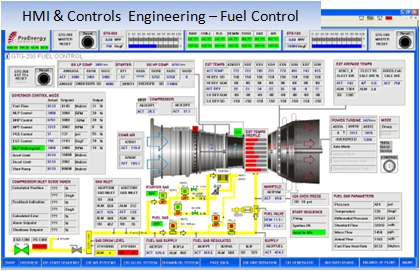

ProEnergy, Jan 2010 to Dec

2010: Venezuela:

· Sr. Controls Field Service Engineer - El Furrial Power Plant,

supervise commissioning

and installation activities, assess the needs and suggest modifications /

repairs for this 232 MW Power Plant.

4x RR Trent 60 III and support Thermozulia

General Electric FR7EA · Sr. Controls Field Service Engineer - La Raisa Power Plant: Supervise

commissioning and installation activities, assess any needs and suggest

modifications and or repairs for this 179 + 179 MW Power Plant. Successfully completed the Pratt

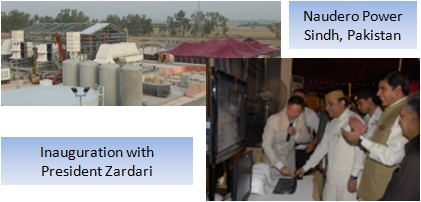

&Whitney FT8 GTG Early Start project (Phase I) Pakistan: · Lead Field Engineer Electrical and Controls: - Supervision of 16 field service engineers and

skilled trades. Naudero Power Project, Sindh

Province for ProEnergy. Extensive

field engineering was required for this controls system retrofit and the commissioning of

2x 1980s de-commissioned RB211, including the complete programming a one of a kind PLC, start sequencing logic, alarming a

protection controls, the creation of a new and independent fuel algorithm for

gas turbine fuel control, lube oil control and flow scheduling and complete

HMI development including all operator interfaces and diagnostic tools. Contract:

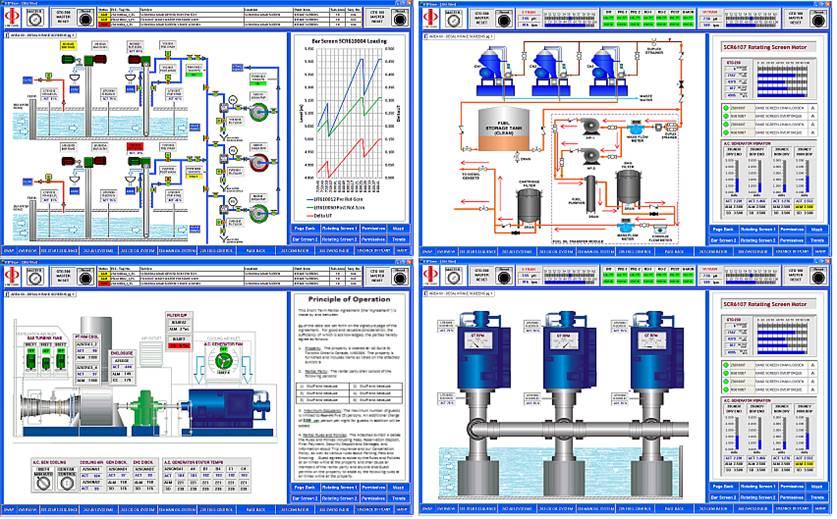

Rolls Royce Energy Systems Apr 1996 to Dec 2009: Senior Field Service Rep, Controls Specialist: Canada · Husky

Energy, Sea Rose, FPSO Offshore Grand Banks: Lead controls, commissioning

and long-term service agreement for 3 x RB211 Dual Fuel Turbine Generator

Sets. Provide emergency assistance, maintenance, inspections. Work with site

operator’s maintenance staff, provide custom training sessions · Shell Canada, Waterton Gas Plant, Alberta Lead for controls system retrofit / commissioning

of 2x RB211; Sequencing, Fuel Control and HMI development. · London

Health Sciences Corp, Ontario

Develop, install and commission HMI Operator

Interface and Data Acquisition System, support the new Co-Generation Plant

Start up. Brazil: · Fafen Petrochemical, Camacari, Bahia: Provide

Training to the Power Plant Manager and provide technical support. Develop

and implement the maintenance plan for controls, Modifications for improved

diagnostics, reliability and availability. · Offshore, Petrobras P48 & P43 FPSOs Lead Controls for 8x RB211s from construction

through offshore operation. Russia: · Northern

Lights Refinery: Lead

installation and commissioning of a third Allison KB5 gas turbine generator,

paralleling and load sharing in island mode in a harsh arctic environment. Gulf of México: · Offshore Pemex, Platforms Abkatun Alpha &Delta, Final Commissioning controls retrofit Allison KB5

and resolve issues relating to start reliability and generator load sharing. ..

more work history beginning 1981 is available upon request |

|